OUR PRODUCT

Regarding quality as the life of the enterprise, strictly controlling product quality, and doing our best for customers to the greatest extent possible!

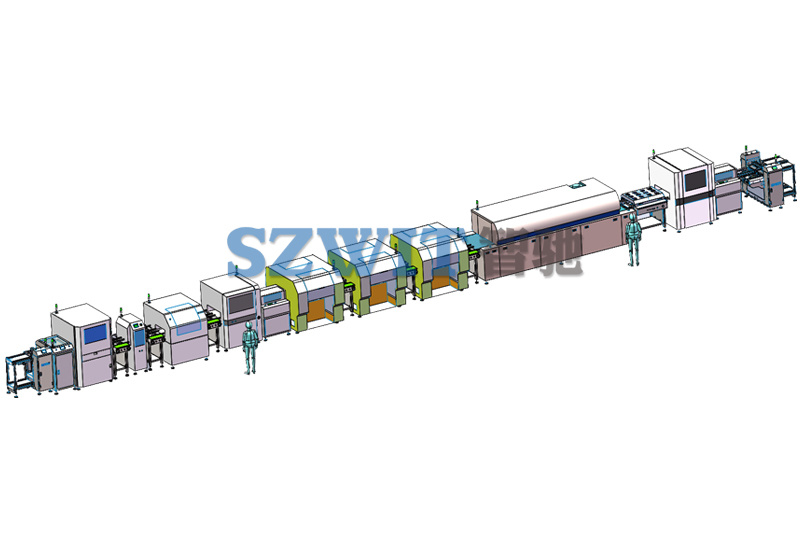

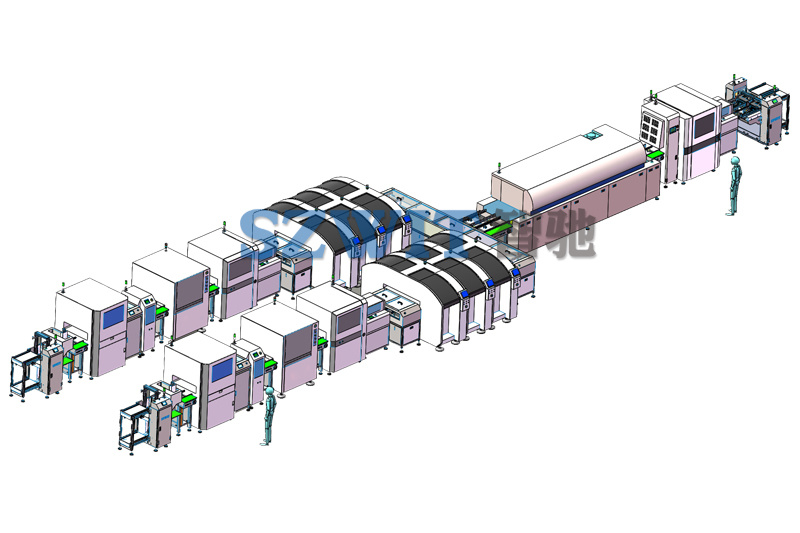

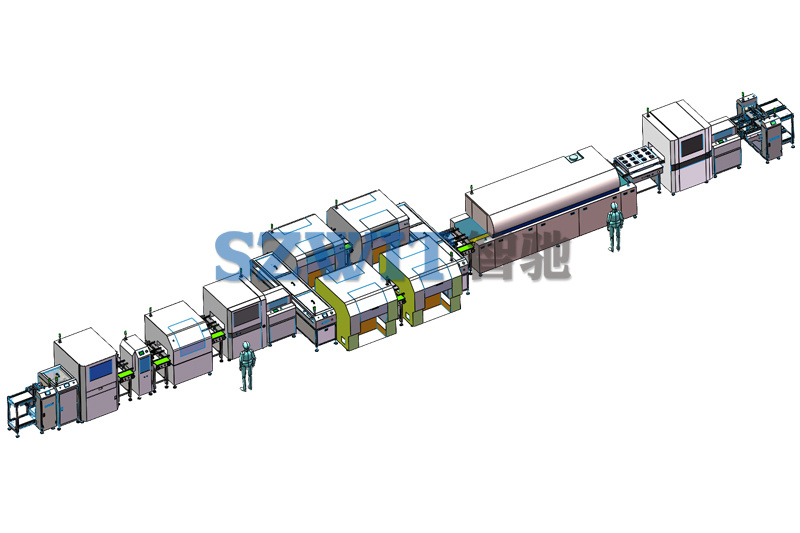

Turnkey SMT Production line solution

Full SMT line solution,Smart Digital SMT Factory, the ability to solve existing and future problems,allows solutions to be implemented at the speed of business while creating advantaged value

Smart manufacturing technology increases efficiency. It’s chighly connected, knowledge-enabled, leading to enhanced productivity, sustainability, and economic performance

Supporting Equipment and Customization

We are able to customizing, This is the necessary device for SMT assembly line and are capable to make assembly line smarter

PRODUCT CENTER

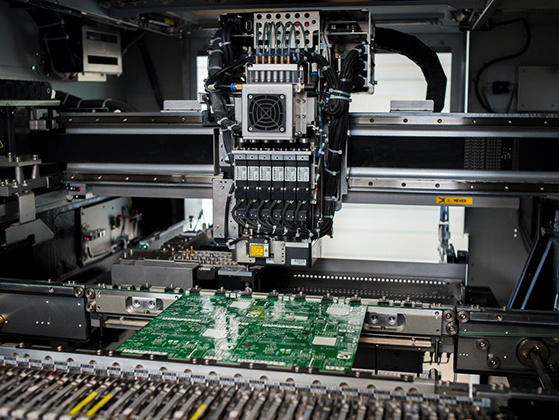

High Speed JUKI SMT SMD Production Line

SZWIT core technology team has more than 15 years of experience in SMT/DIP technology, providing customers with more SMT/DIP solutions.

High speed SMT production Line

SZWIT core technology team has more than 15 years of experience in SMT/DIP technology, providing customers with more SMT/DIP solutions.

Fully Automatied SMT SMD Line Machine

SZWIT core technology team has more than 15 years of experience in SMT/DIP technology, providing customers with more SMT/DIP solutions.

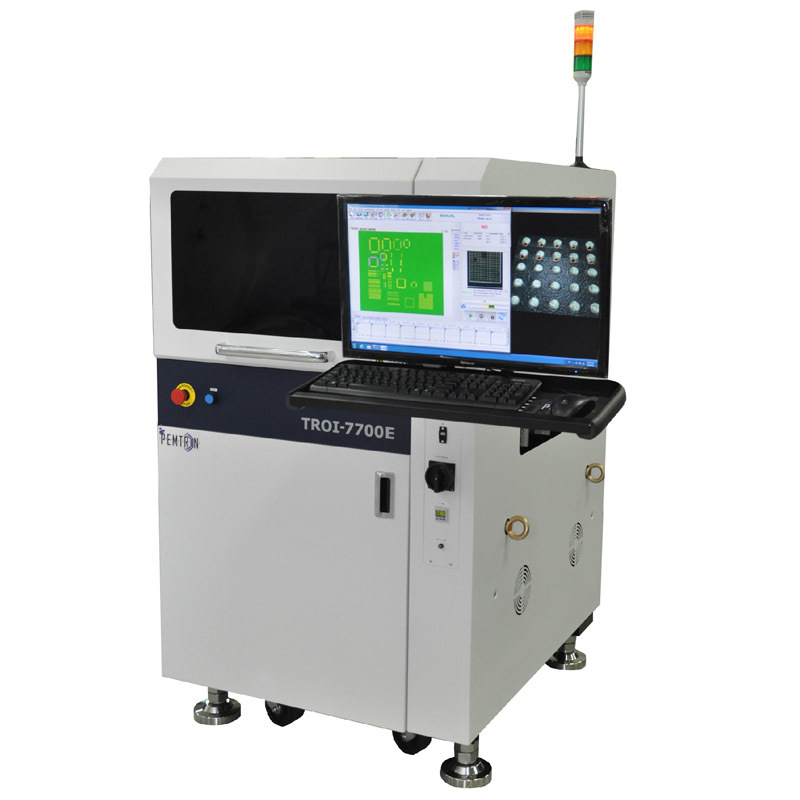

PEMTRON 3D SPI

Using the principle of optics, the height of the solder paste printed on the PCB board is calculated by the method of triangulation

ABOUT US

One-stop SMT Solution Provider, Your Industry Expert.

SZWIT was founded in 2008 in Shenzhen as a SMT machine and parts provider, We delicated to continually expanding our supply network and resources to provide one-stop solutions for the elctronics manufacturers. Our wealth of experience and professional industry knowledge helps our customers gets the right solutions.

Factory area

Annual sales

Customers

SZWIT Your SMT/DIP Transmission Solution Center

27

2025-11

How Wave Soldering Machine Works: Process and Benifit

In the world of electronics, there’s something deeply satisfying about watching a complex Printed Circuit Board (PCB) come to life. It’s not just the assembly of components; it’s the artistry of making connections—tiny bonds that bring technology into motion. Behind this process, wave soldering equipment quietly plays a vital role, forming the unseen foundation of our digital age

11

2025-11

How to Choose the Right Conformal Coating Equipment for Your Application|SZWIT

Modern times demand a lot of reliability; reliability is not for luxury, but it is necessary to know about the details of all the electronic products you buy. You are here to read about conformal coating implies that you're designing a cutting-edge aerospace system or an automotive ECU. But how will you protect your PCBs from moisture, dust, and chemical contaminants? Knowing the fact that there are so many Conformal Coating Systems available, how do you choose the Right Conformal Coating Equipment for your specific application? Keep reading this blog to get a thorough walkthrough about the same.

Follow Us

Scan to follow the official account

Service Hotline

+86 18665891623

Email:Rylee.young@szwit.com

Tel: +86-755-27456080

Company Address: Fuyong street, Bao'an District, Shenzhen

2nd floor, building 11, Huafeng Science Park, Tangwei