Product

UV Inspection Conveyor

This is used at end of conformal coating line, it’s designed to frequent visual inspection of PCB’s is required.

View More

Full-auto SMT stencil printer

1. The scraper seat is driven by precision guide rail and loose speed motor to ensure printing accuracy.

2. The printing squeegee can be rotated up to 45 degrees and fixed, which is convenient for cleaning and replacement of the printing screen and the squeegee.

3. The scraper seat can be adjusted back and forth to choose the appropriate printing position.

4. The combined printing platen has fixed grooves and PINs, which are easy to install and adjust, and are suitable for single and double-sided printing.

5. The proofreading method adopts steel mesh movement, combined with the X, Y, Z correction and fine adjustment of printing (PCB), which is convenient and quick.

6. It adopts PLC and touch screen control, which is simple, convenient and suitable for man-machine dialogue.

7. One-way and two-way can be set, a variety of printing methods.

8. With automatic counting function, it is convenient for the statistics of production output.

9. The angle of the scraper is adjustable, both steel scrapers and rubber scrapers are suitable.

10. The touch screen has a screen saver function, and the time can be adjusted arbitrarily to protect the service life of the touch screen.

11. It has the function of wiping the screen and alarming, which is convenient for cleaning the screen on time and guarantees the printing quality.

12. Using AE's unique program design, the printing scraper seat is easy to adjust.

13. The speed of the printing press is displayed, which can be adjusted arbitrarily.

14. The upper and lower lifts use special cylinders to ensure stable work.

View More

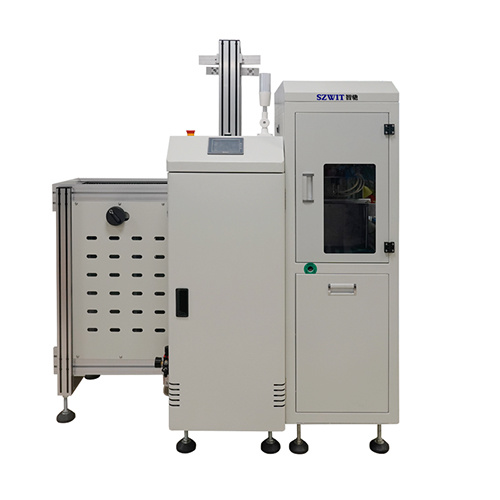

PCB Loader

Equipped at the start terminal of SMT/DIP line, sensors are provided to prevent platform movement until the board has been fully inserted into the magazine automatically. reducing labor cost, increasing production efficiency.

View More

FIFO Buffer

This The FIFO buffer is used on SMT or conformal coating line with 2 main functions:

View More

NG&OK Unloader

TEquipped at the end of SMT and DIP production line, automatically stores NG and OK boards separately by receiving signals from inspection machine. Automatic entry and exit, short cycle time, enhances efficiency and product quality.

View More

PCB cleaning machine

This unit is equipped in front of solder paster or before conformal coating process, The machine uses specially formulated elastomer rollers to remove dust, particles, etc. from the PCB surface. This contamination is transferred from the elastomer rollers to adhesive rolls.

View More

Cooling Buffer

This device combined cooling and storage functions, used to cool the PCB after Reflow Oven in FIFO way.

1.Cooling PCB in FIFO way, avoid aging of AOI camera and conveyor belt. Reducing Thermal expansion and cold contraction, decreasing misjudgment rate of AOI machine.

2.Storage function to mitigate the traffic stress of PCB stack.

View More

Sucking loader

The first station of SMT production line, deliver the board to next station automatically, Combining Vacuum and magazine feed for single and double sides board. This integrated function enhances overall efficiency of your production.

View More

PCB Unloader

This unit is used to collect PCBs into magazine at the end of SMT/DIP or testing production line. The PCB's are collected from upstream machine using attached conveyor and pushed into the magazine automatically. Avoid manual touch, reducing labor cost, increasing production efficiency.

View More

Dual-rails Unloader

It’s used at the end of dual rails of SMT/DIP/Testing production line. The PCBs are collected from upstream machine onto a shuttle conveyor and pushed into designated magazine. Shuttle conveyor moves sideways between upstream machine and magazines.

View More

PCB Shuttle Conveyor

The PCB shuttle conveyor can be used for transporting boards from one line into two lines or vice versa of SMT and DIP. he PCB board transport from one-track machine to dual-track placement machine for subsequent production. Separate production line as 2-in-1 or 3-in-1, save labor cost and space, optimize equipment capability, improve production efficiency.

View More

Follow Us

Scan to follow the official account

Service Hotline

+86 18668591623

Email:songxinhui@szwit.com

Tel: +86-755-27456080

Company Address: Fuyong street, Bao'an District, Shenzhen

2nd floor, building 11, Huafeng Science Park, Tangwei